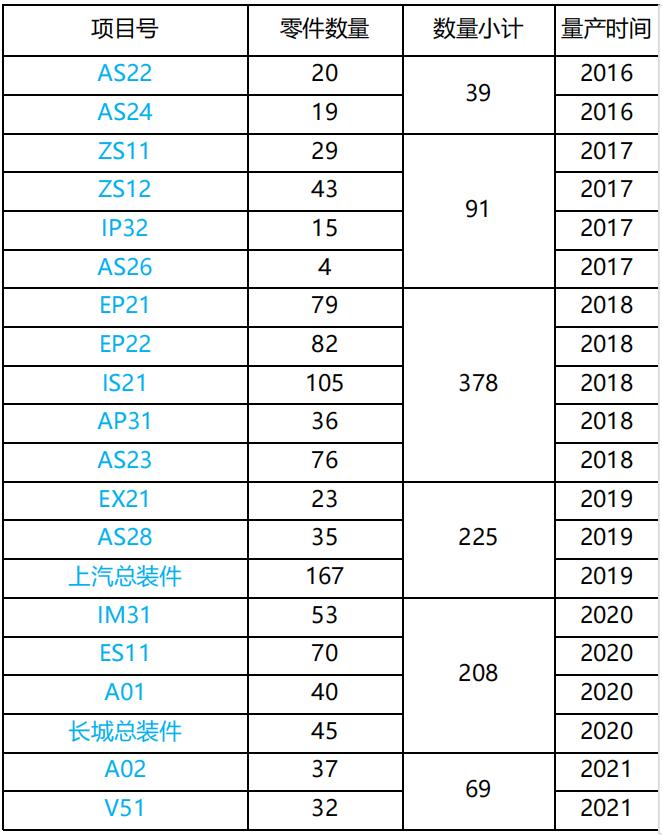

Since 2015, Jiangsu Baorui has completed a total ofAS22、AS24、ZS11、ZS12、IP32、EP21、EP22、IS21、 AS26、AP31、EX21、AS23、AS28、IM31、ES11、A1、A02、V51And other 18 projects, which are divided into body parts and assembly parts, with 1010 parts supply units developed; Es11, A1, A02 and V51 are great wall motor projects, and the remaining 14 are SAIC passenger car projects; Main customers: SAIC passenger cars, Great Wall Motors.

|

序号 |

车型 |

项目号 |

所属厂商 |

备注 |

|

1 |

尚界 |

SHA |

上汽乘用车 |

|

|

2 |

荣威D5X |

AS33 |

上汽乘用车 |

|

|

3 |

名爵ZS |

ZS32 |

上汽乘用车 |

|

|

4 |

名爵HS |

AS23 |

上汽乘用车 |

|

|

5 |

荣威RX8 |

IS21 |

上汽乘用车 |

|

|

6 |

荣威i5 |

AP31 |

上汽乘用车 |

|

|

7 |

荣威D7 |

EP39 |

上汽乘用车 |

|

|

8 |

名爵6 |

IP32 |

上汽乘用车 |

|

|

9 |

名爵5 |

AP32 |

上汽乘用车 |

|

|

10 |

名爵3 |

ZP22 |

上汽乘用车 |

|

|

11 |

荣威Ei5 |

EP22 |

上汽乘用车 |

|

|

12 |

飞凡F7 |

EH35 |

上汽乘用车 |

|

|

13 |

MG ONE |

AS32 |

上汽乘用车 |

|

|

14 |

荣威鲸 |

AS28-M3 |

上汽乘用车 |

|

|

15 |

荣威RX9 |

IS31 |

上汽乘用车 |

|

|

16 |

荣威iMAX8 |

IM31 |

上汽乘用车 |

|

|

17 |

MG-Cyberster |

EC32 |

上汽乘用车 |

|

|

18 |

MG 7 |

IP42 |

上汽乘用车 |

|

|

19 |

名爵ES5 |

MZS3E |

上汽乘用车 |

|

|

20 |

荣威D6 |

AP4ER |

上汽乘用车 |

|

|

21 |

MG 4 |

AH4EM |

上汽乘用车 |

|

|

22 |

欧拉好猫 |

ES11 |

长城汽车 |

|

|

23 |

哈弗jolion |

A01 |

长城汽车 |

|

|

24 |

哈弗赤兔 |

A02 |

长城汽车 |

|

|

25 |

欧拉芭蕾猫 |

ES13 |

长城汽车 |

|

|

26 |

哈弗酷狗 |

A08 |

长城汽车 |

|

|

27 |

欧拉闪电猫 |

EC24 |

长城汽车 |

|

|

28 |

哪吒L |

EP32 |

哪吒汽车 |

|

|

29 |

理想-i6 |

W04 |

理想汽车 |

|

|

30 |

理想-i8 |

W02 |

理想汽车 |

From 2015 to 2020, the total number of developed parts is 1010 supply units:

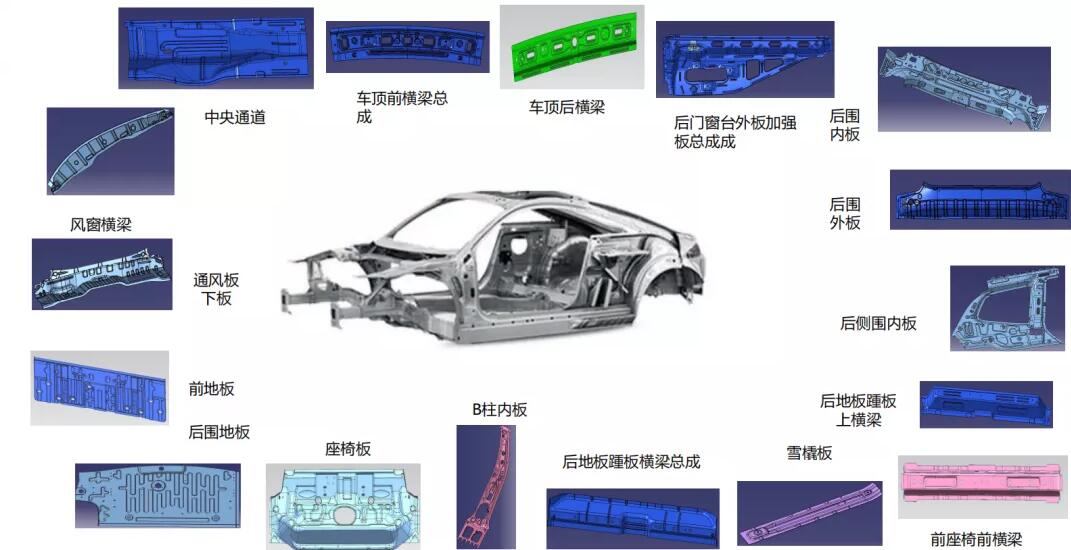

SAIC project, class B case: ventilation panel, windshield beam, central passage, front floor, rear wall floor, seat panel, rear wall inner and outer panel, window sill reinforcement panel, side wall inner panel, floor heel plate beam, B-pillar inner panel, ski board, etc

SAIC project, a typical case of class C parts:

Great Wall Project: middle and rear floor assembly:

General Assembly cases: TCU bracket, ECU bracket, engine HARNESS Parts, brake disc guard, esp bracket, electronic vacuum pump bracket, detection radar bracket, air filter bracket, front and rear oxygen sensor bracket, electronic water pump bracket, brake regulator module bracket, air filter bracket, headlamp bracket, battery tray bracket, ceiling handle bracket, front and rear bracket of auxiliary instrument panel Seat shaft bracket assembly, child seat hook mounting plate assembly, ventilation cover plate mounting plate, overflow tank bracket, high temperature sensor bracket, hood lock mounting bracket, etc;

Process involved: electrophoresis, electrophoresis after galvanizing, galvanizing nickel