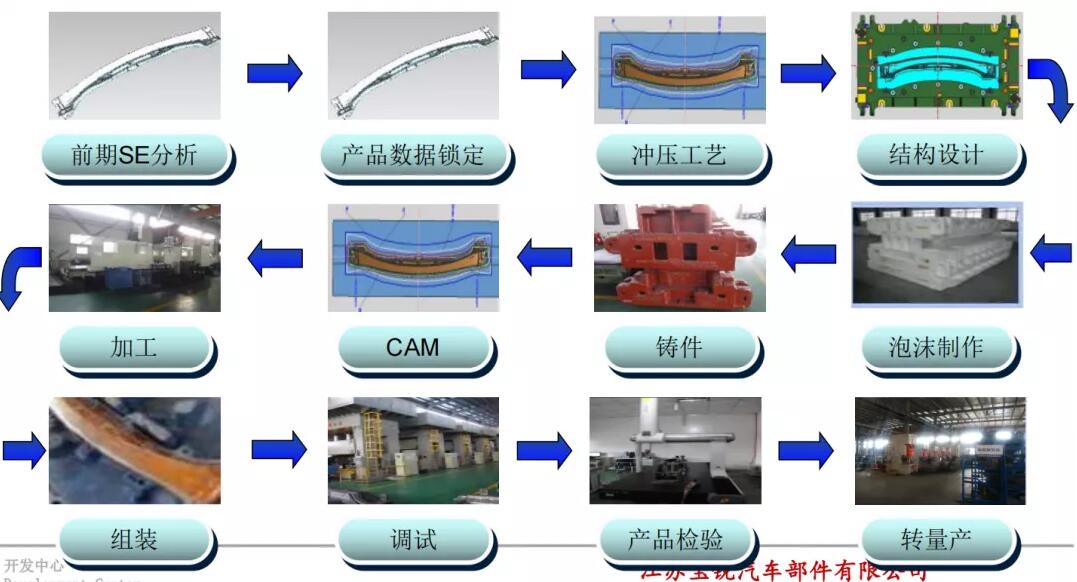

Mold manufacturing process

From the early docking with customers se analysis, to the parts of the mold design, development and manufacturing process control, established a perfect mold manufacturing management process

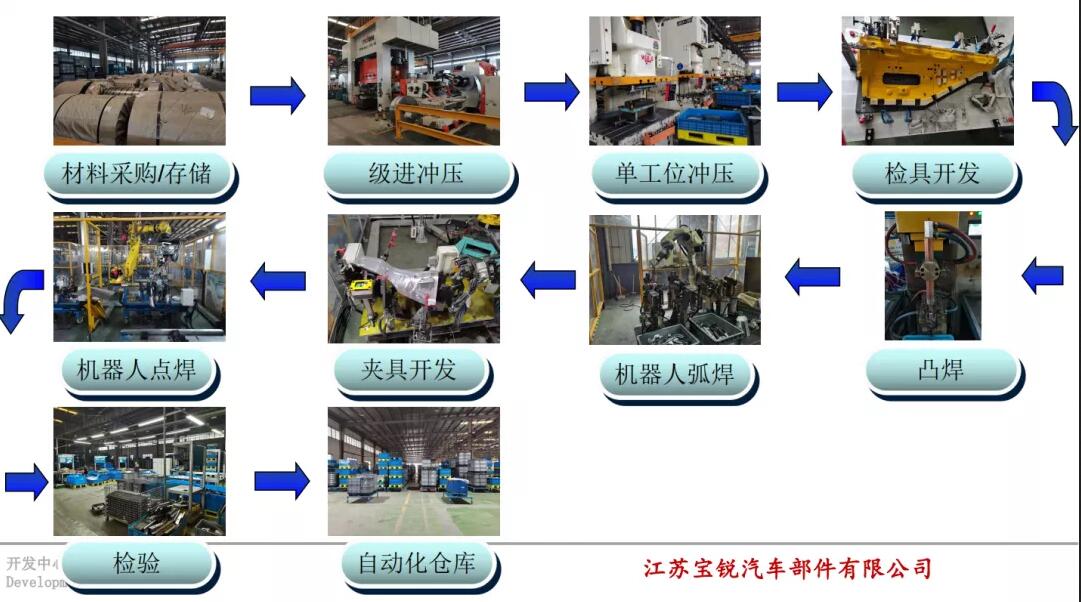

Parts manufacturing process

From raw material procurement, storage, order management, fixture development, parts stamping, welding production to inspection, warehousing and delivery, a complete automatic and large-scale manufacturing management system has been formed

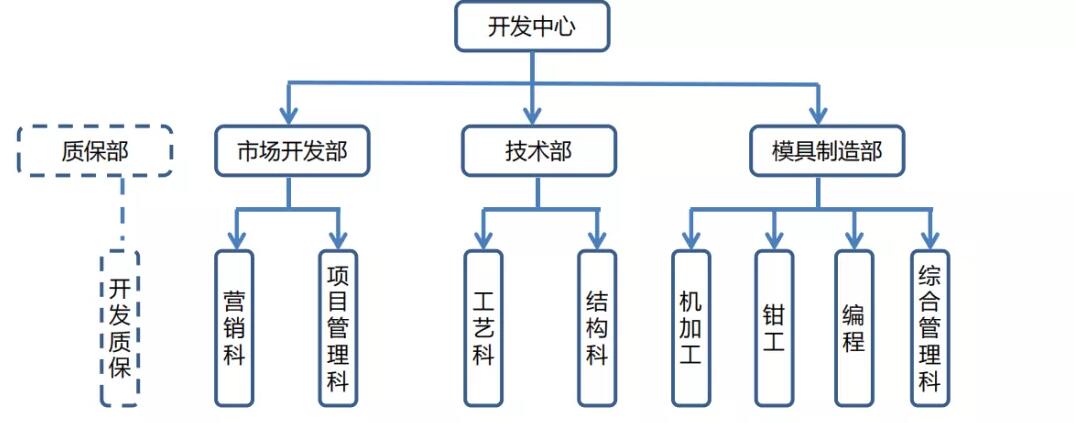

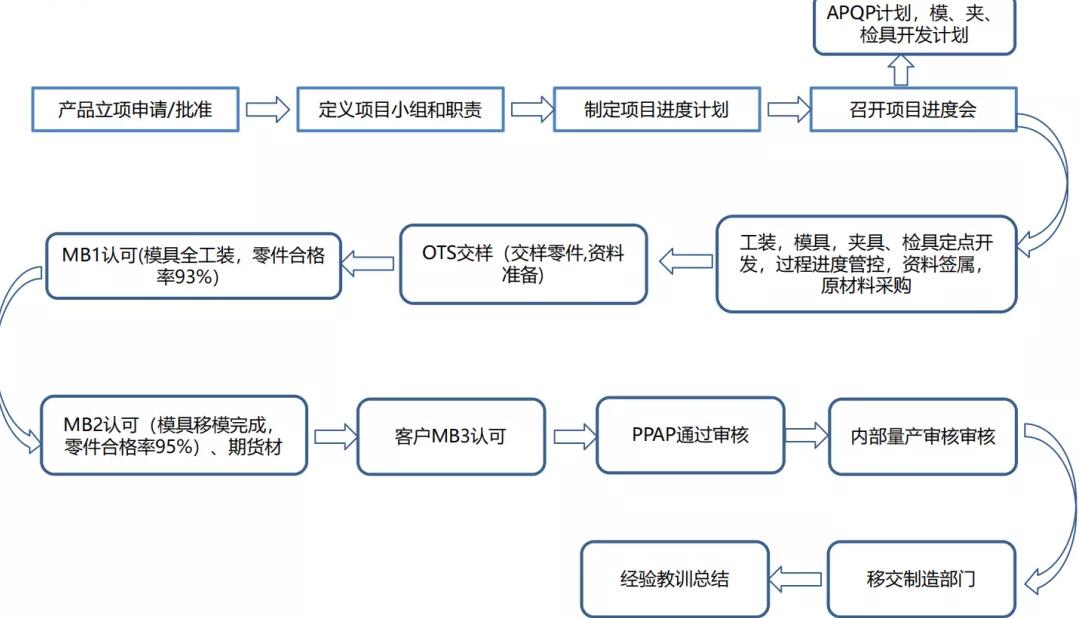

Project development process

Project Team Introduction: project development mode is a development mode in which the development center is in charge and other departments participate together. The development center covers marketing, project management, technology and mold manufacturing departments

There are 6 project managers in the project management section, one of whom is responsible for the final assembly project, and the other is responsible for the body parts project management. He has 4-8 years of project management experience, and has been engaged in the project management of Kia, Dongfeng / GAC Honda, SAIC passenger car, SAIC GM and great wall motor, and has great experience in the project management of single piece and welding assembly

Development quality assurance: there are three people in the quality assurance department, who are specially responsible for the development of new projects with 3-5 years of working experience. They have been engaged in the development quality work of SAIC passenger car, GM Wuling and great wall motor

Other team members: when the project is approved, each department formulates fixed personnel to participate in the project development until the end of the development and transfers to mass production for three months, and the professional project team cancels

Project management process

Product Name: front seat front cross member (SAIC project)

HC420/780DP/1.4mm

Process setting: Op10 (forming) OP20 (trimming) op30 (flanging) op40 (flanging) op50 (side shaping) op60 (punching side punching side shaping)

process setting: Op10 (forming) OP20 (flanging) op30 (flanging) op40 (flanging) op50 (side shaping)

Process Description: multiple flanging, side finishing process

Development difficulties: high strength plate, large side wall rebound; Project (process): early CAE actuarial, rebound compensation

Product Name: central channel (SAIC project)

HC340/590DP/1.0mm

Process setting: Op10 (stretching) OP20 (trimming and punching) op30 (flanging and shaping) op40 (punching and trimming)

process setting

Process Description: whole drawing

Development difficulties: high strength plate deep drawing, side wall reverse arc springback is large

Scheme (process): CAE actuarial in early stage, whole drawing, easy to compensate springback

Product Name: left / right threshold beam (Great Wall Project)

HC340/590DHD+Z/1.6mm

Process setting: Op10 (stretching) OP20 (trimming and punching) op30 (trimming and separating side trimming) op40 (side trimming) op50 (punching side punching)

Process Description: left and right clamping, whole drawing

Development difficulties: high strength plate deep drawing, side wall reverse arc springback is large

Scheme (process): CAE actuarial in early stage, whole drawing, easy to compensate springback

Product Name: rear door window sill outer plate reinforcing plate (SAIC project)

HC340/590DP/0.7mm

Process setting: Op10 (stretching), OP20 (trimming and punching), op30 (flanging and flanging), op40 (separating and punching) and op50 (flanging and punching)

Process Description: left and right clamping; Development difficulties: poor rigidity of parts and many matching surfaces

Scheme (process): stretch as far as possible to increase rigidity and reduce springback of parts